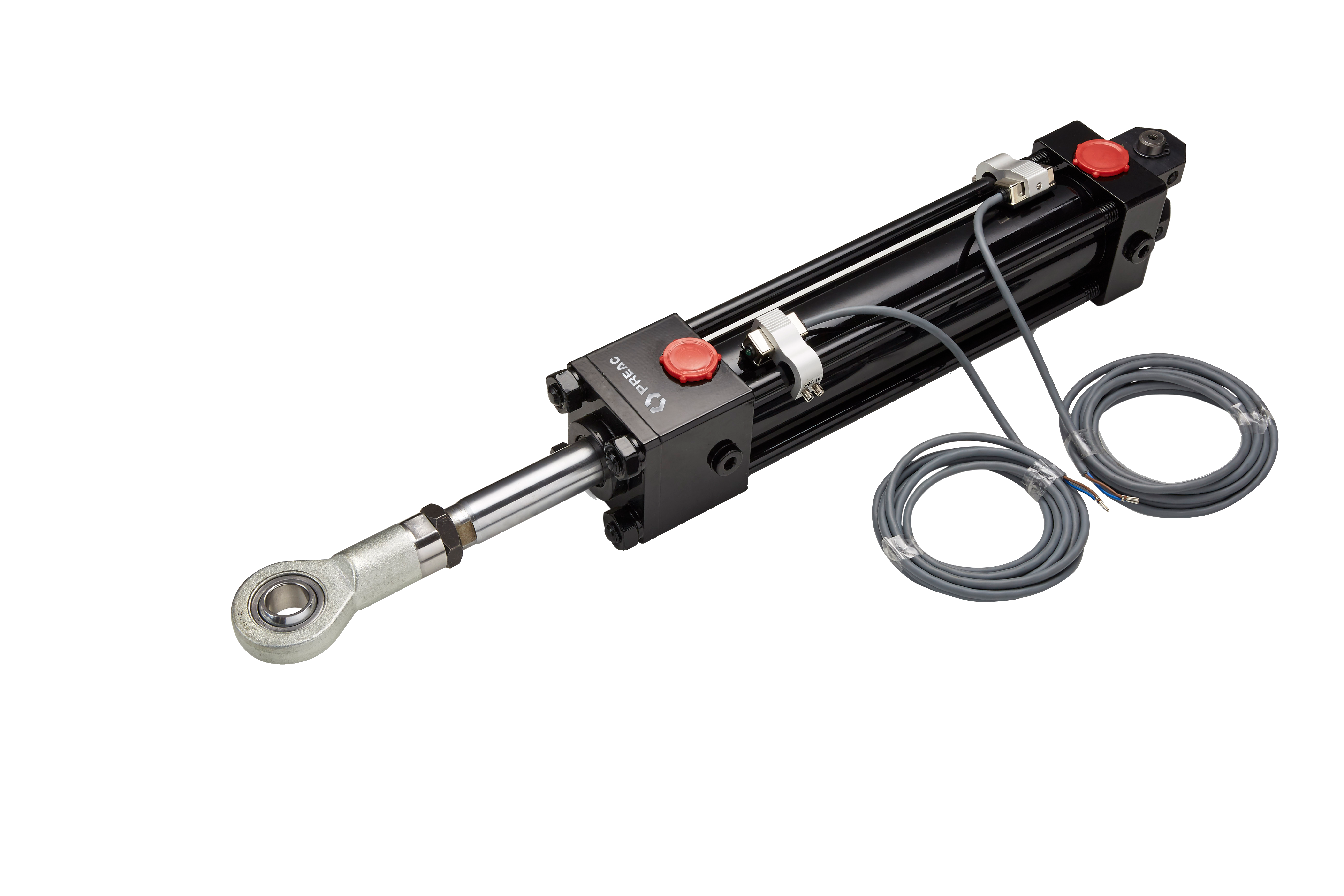

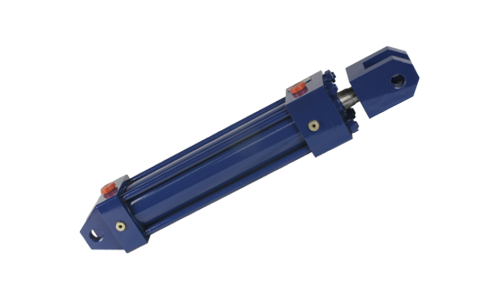

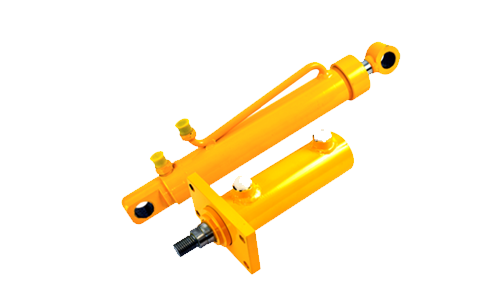

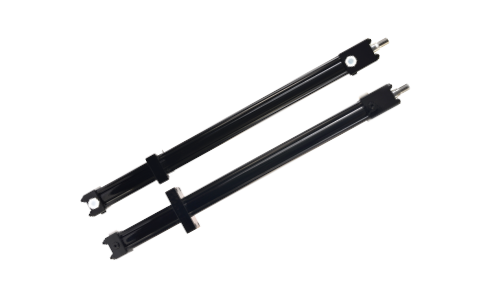

LH7 Series

(Rated pressure: 50 kg/cm²)

Tie-rod type, Medium Pressure hydraulic cylinders, available with a wide range of mounting arrangements conforming to CETOP recommendations.

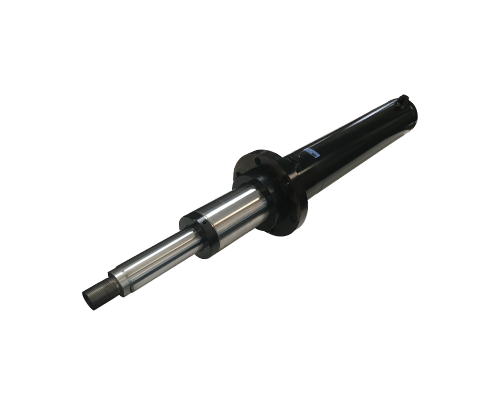

Specifications

- Rated pressure 50 kg/cm².

- Peak pressure 70 Kg/cm².

- Cylinder bore diameters: 25mm to 350mm.

- Strokes up to 3000 mm.

- Temperature range: -20°C to 90°C. (Optional sealing systems for temperatures up to 180°C)

Application

These cylinders are designed and constructed for high duty cycles in Machine Tool applications.