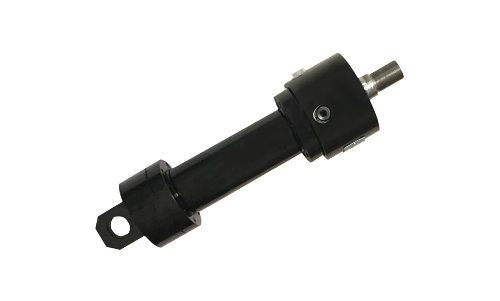

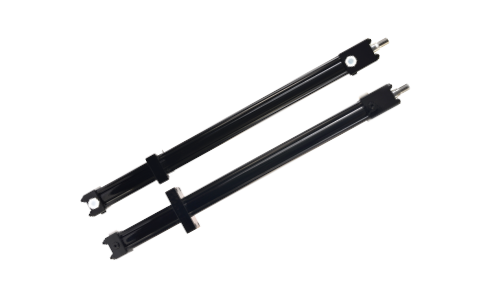

4110 Series

These cylinders are Pull-Type cylinders where the piston rotates by 90° (CW or CCW) during the swing stroke and then travels in a straight line during the clamping stroke. A solid one-piece construction ensures perfect alignment of internal components and maximum clamping rigidity.

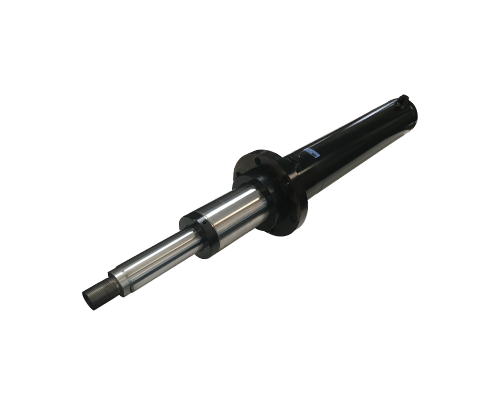

Specifications

- Type: Double Acting, Top Mounted.

- Bore diameters: 40 mm to 63 mm.

- Clamping forces up to 900 kgf.

- Rated pressure: 160 kg/cm².

- Standard clamping stroke: 14 mm.

- Special bores and longer strokes available on request.

Application

Hydraulic Swing Cylinders are used for clamping where it is necessary to keep the clamping area clear for unrestricted loading and unloading of work pieces.